ZTE Corporation, a global leader in integrated ICT solutions, has joined forces with TrueBusiness (under True Corporation, Thailand’s leading telecom-tech company) and Charoen Pokphand Foods (CPF) to deploy a 5G smart factory using an independent private network called 5G-in-a-box at CPF’s facility.

This pilot deployment marks a significant milestone in CPF’s digital transformation efforts and supports Thailand’s Industry 4.0 strategy. Traditional Wi-Fi networks in the food manufacturing sector have struggled to meet the growing demands of intelligent manufacturing due to limitations in security, latency, coverage, and reliability.

Latest Network News: ZTE Launches G6 Series Servers, Boosting Green Computing Infrastructure

5G-in-a-Box

To overcome these challenges, CPF, in collaboration with ZTE and TrueBusiness, implemented the 5G-in-a-box solution, showcasing its transformative capabilities and advancing CPF’s digital journey. The project leverages True’s dedicated spectrum and employs network slicing technology to ensure high-quality service and enterprise-grade security. Cost-effectiveness was a priority, resulting in the selection of ZTE’s iMacro equipment, which is ideally suited for food factory environments. Its external installation on glass walls minimizes contamination risks associated with water cleaning and food safety protocols.

ZTE’s advanced iMacro and UniEngine technologies have been instrumental in building this independent 5G private network. The solution addresses the limitations of traditional Wi-Fi while simplifying 5G deployment and operations. UniEngine, a critical component of the network, delivers a low-maintenance, high-performance solution with integrated computing, seamless network integration, and deterministic Service Level Agreements (SLAs).

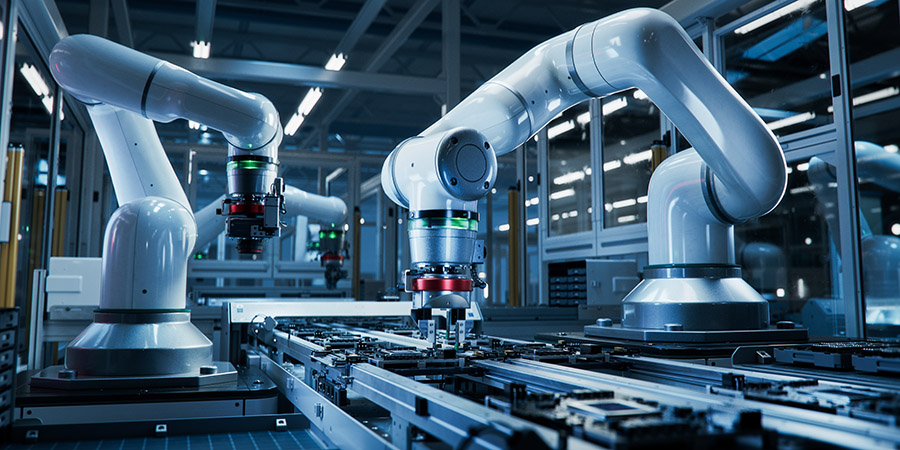

The 5G-in-a-box deployment at CPF’s Center of Engineering Excellence (CEE) represents a major breakthrough. As an innovation hub, CEE invites CPF’s business groups to explore technologies such as robotics and energy management. This initiative aims to enhance production processes, improve efficiency, reduce costs, and promote sustainable growth while upholding social and environmental responsibilities.

Related: ZTE, CelcomDigi Revolutionize Malaysia’s Manufacturing Industry

5G-Driven Industrial Modernization

The integration of 5G at CEE strengthens communication between machines, humans, and control systems, improving data reliability through ZTE’s robust coverage and penetration capabilities. The deployment supports advanced applications such as autonomous guided vehicles (AGVs), robots, vision inspection, AI, and more. Achieving an average latency of just 10 milliseconds, the solution enables precise traffic differentiation and seamless data transmission. With a downstream speed of 882 Mbps, it eliminates wiring constraints while ensuring 99.99% equipment reliability, establishing a strong foundation for deterministic networks and the future of smart manufacturing.

This groundbreaking collaboration underscores ZTE’s commitment to fostering connectivity and innovation. The successful implementation at CPF’s factory sets a benchmark for 5G-driven industrial modernization in Thailand, paving the way for widespread adoption and creating significant societal and economic value.

Related:

Smart Factories: The Future of Asia’s Manufacturing Hub

What Industrial IoT Means for the Future of the Manufacturing Sector